How Microchips are Made: The Step-by-Step Fabrication Process

The fabrication of microchips is a highly intricate process that transforms raw materials into the sophisticated components driving today’s technology. The journey from concept to finished product involves several precise and meticulous steps.

1. Raw Material Preparation

The process begins with the selection of high-purity silicon, which serves as the foundational material for microchips. Silicon wafers, typically 6 to 12 inches in diameter, are prepared from this material. The silicon is melted and crystallized into cylindrical ingots, which are then sliced into thin, flat wafers.

2. Wafer Cleaning

Before any circuitry is added, the silicon wafers are cleaned to remove contaminants. This involves several chemical treatments and rinsing to ensure a spotless surface for subsequent processing.

3. Photolithography

Photolithography is a key step where the chip’s circuitry is imprinted onto the wafer. A photosensitive chemical called a photoresist is applied to the wafer's surface. The wafer is then exposed to ultraviolet light through a mask that contains the circuit pattern. The exposed photoresist is chemically treated, creating a pattern that will guide the etching process.

4. Etching

The wafer undergoes etching to carve the circuit pattern into the silicon. Etching removes the unprotected silicon, leaving behind the intricate circuit design. This step can be done using chemical solutions or plasma etching techniques.

5. Doping

Doping introduces impurities into the silicon to modify its electrical properties. This step involves adding elements like phosphorus or boron to create p-type or n-type regions, essential for the chip’s functionality.

6. Layering and Deposition

Multiple layers of materials are deposited onto the wafer to build the chip’s structure. These layers may include metals for connections, insulators, and other materials needed for various components. Each layer is patterned and etched as needed.

7. Testing and Dicing

Once the fabrication is complete, the wafer is tested to ensure that the circuits function correctly. The wafer is then diced into individual microchips, or “dies,” each of which is tested again for defects.

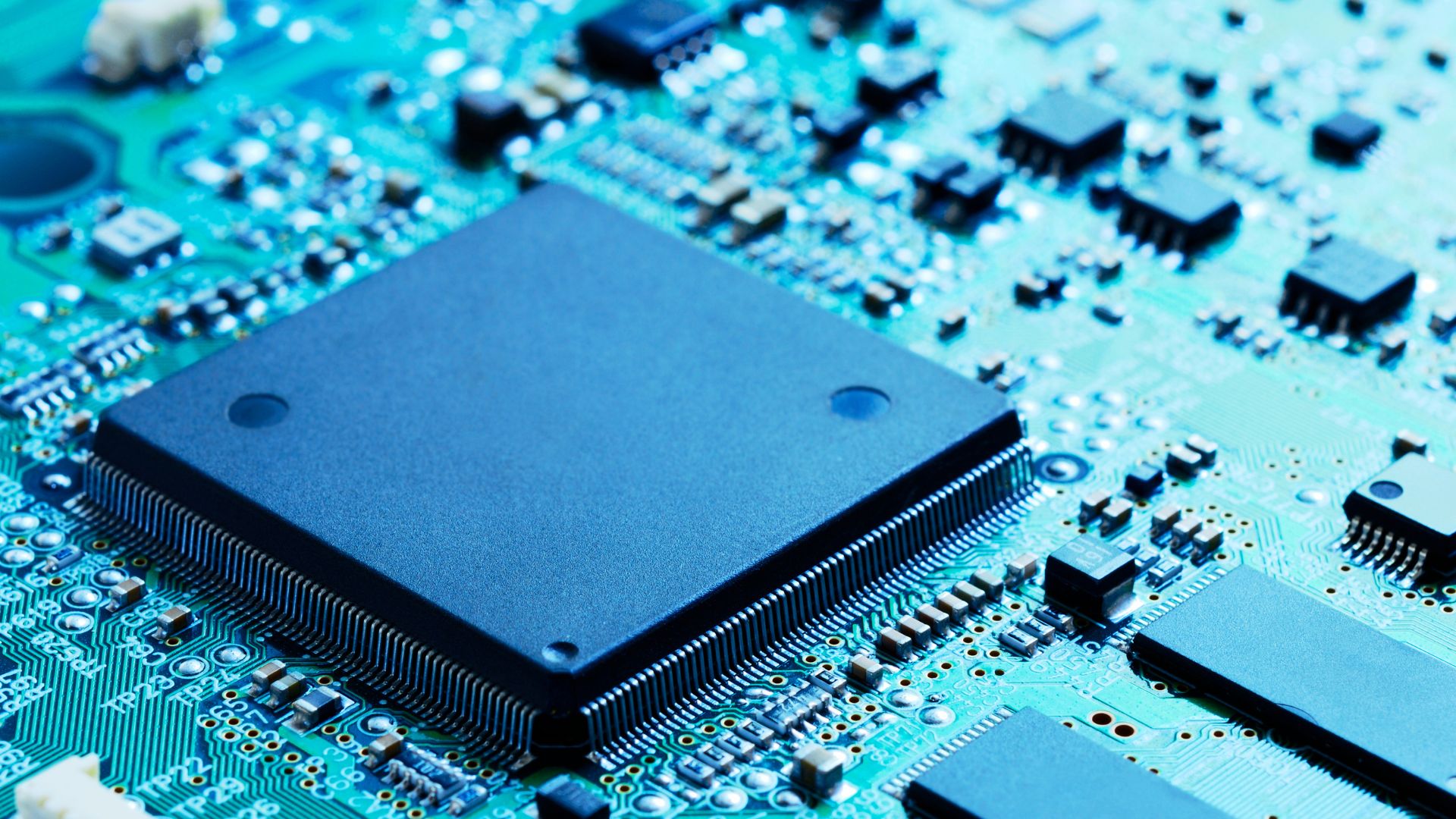

8. Packaging

Finally, the chips are packaged to protect them and facilitate their integration into electronic devices. This involves placing the chips into protective casings and connecting them to external pins or leads.

In summary, microchip fabrication is a complex, multi-step process that requires precision and sophisticated technology. Each stage is crucial in ensuring that the final microchips meet performance and reliability standards, powering the electronics that are integral to modern life.