From Silicon to System: The Lifecycle of a Microchip

The journey of a microchip begins in the labs of engineers, where intricate designs are created to meet specific needs, whether for a smartphone, computer, or vehicle. The process starts with defining the chip's architecture, determining its functionality, power efficiency, and compatibility with other components. Once the design is finalized, it’s time to bring it to life.

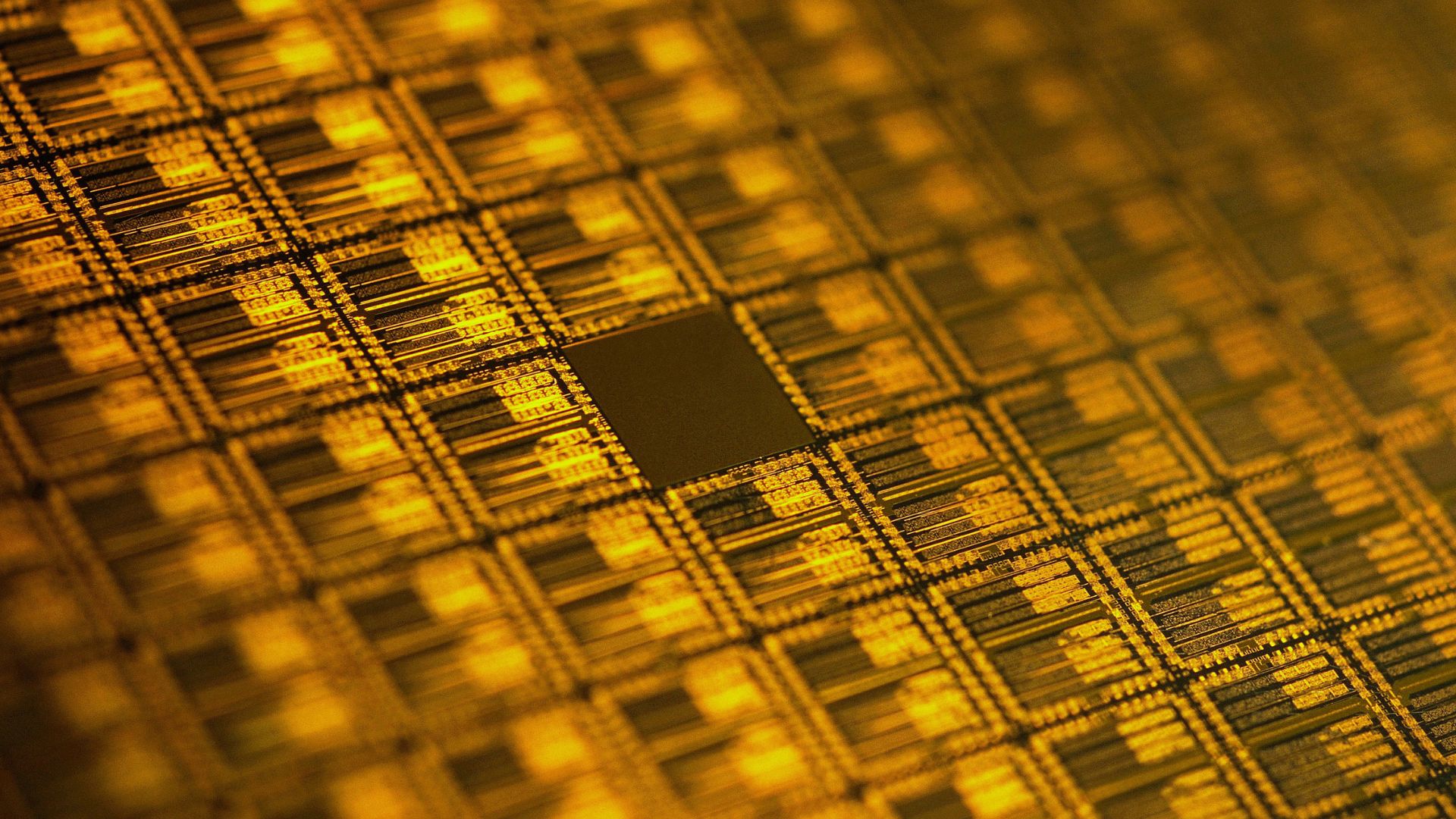

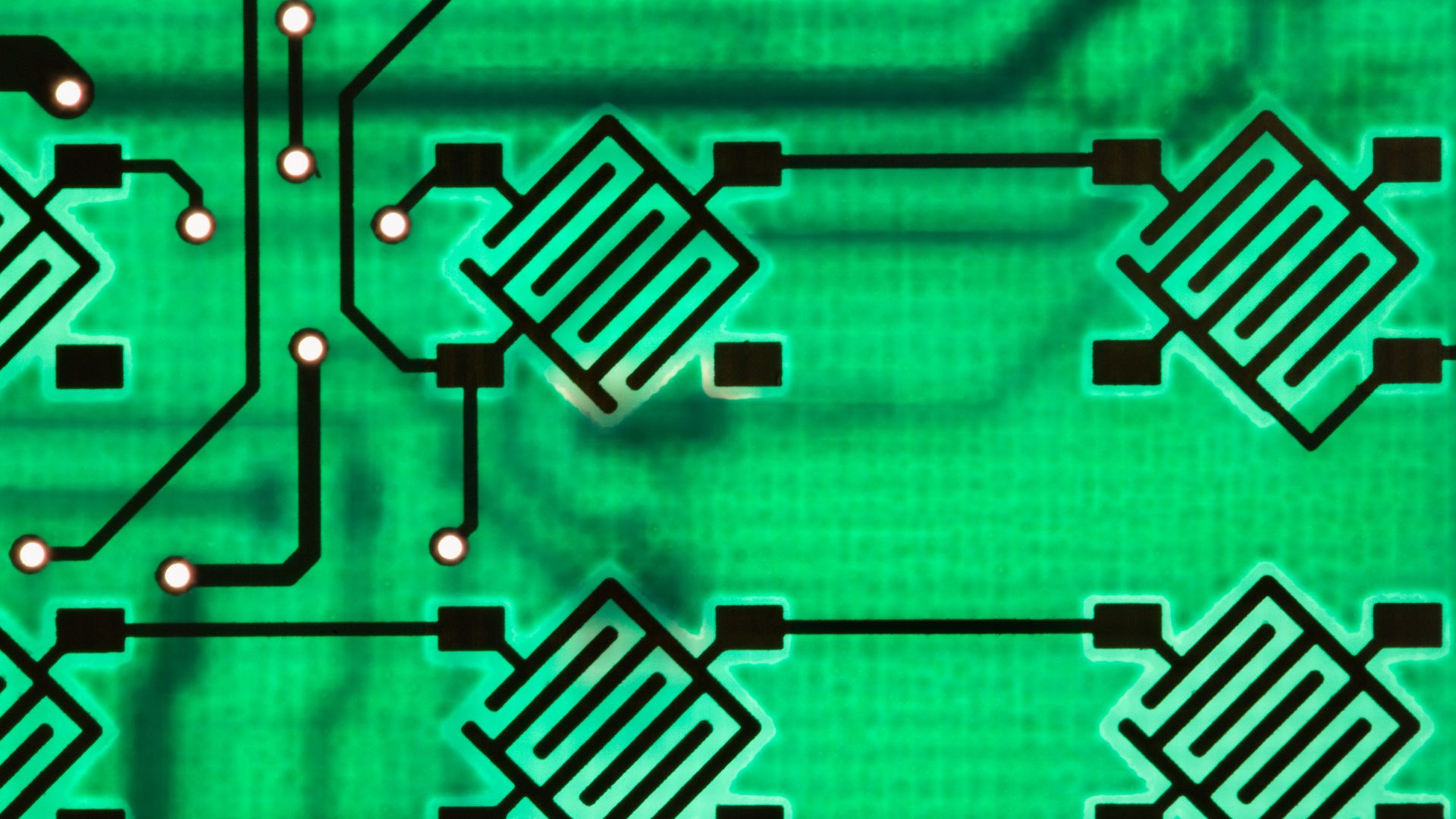

The first material step in the microchip's lifecycle involves silicon, a naturally abundant element, which is purified and transformed into a wafer. This wafer serves as the base for the microchip. Through a process known as photolithography, the intricate patterns designed by engineers are etched onto the silicon wafer, creating billions of tiny transistors. These transistors are the building blocks of the microchip, enabling it to process and store information.

After the transistors are in place, the wafer undergoes several more processes, including doping (adding impurities to alter electrical properties), etching (removing unwanted material), and layering (adding conductive materials). The wafer is then sliced into individual microchips, each ready for testing.

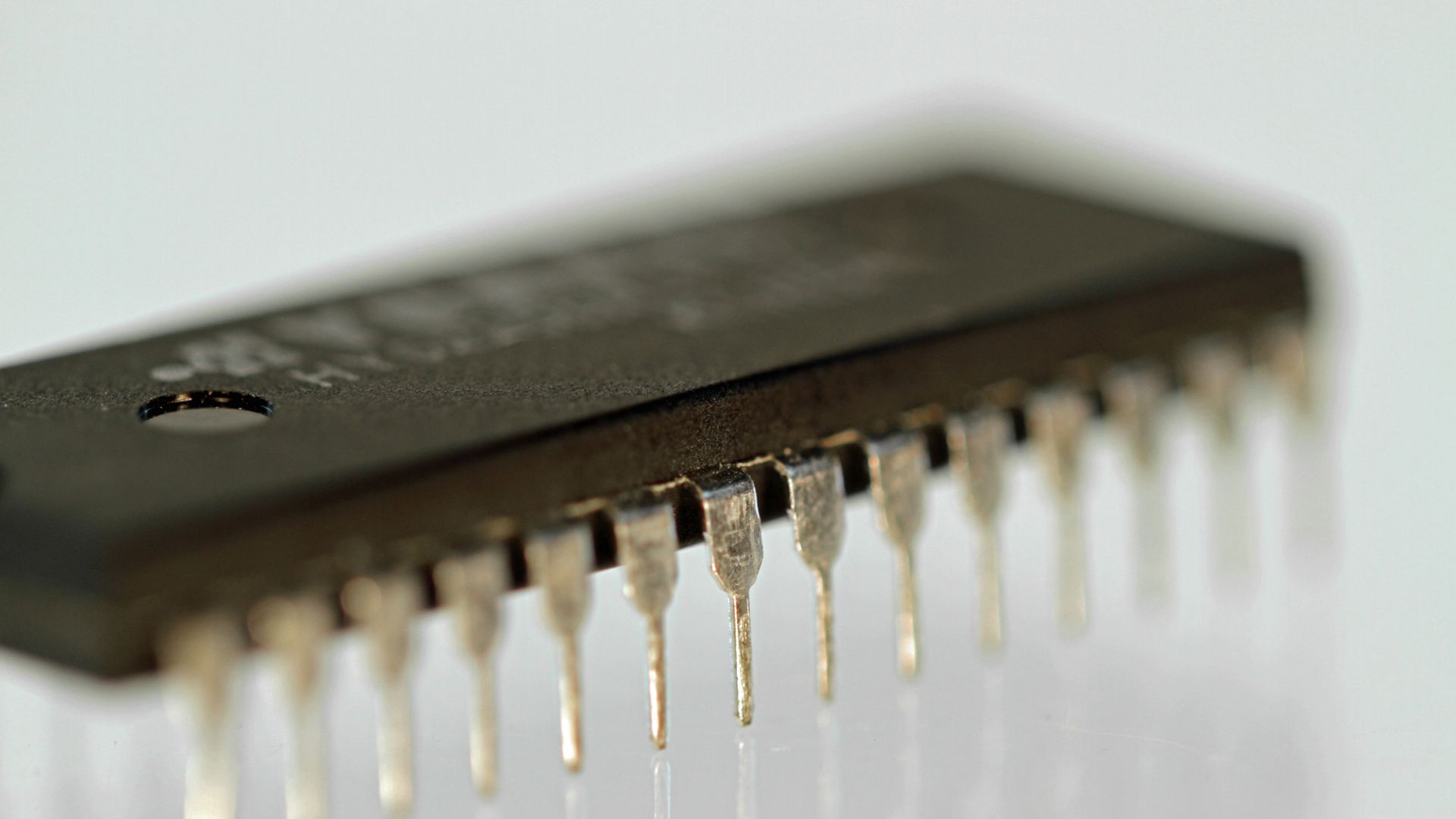

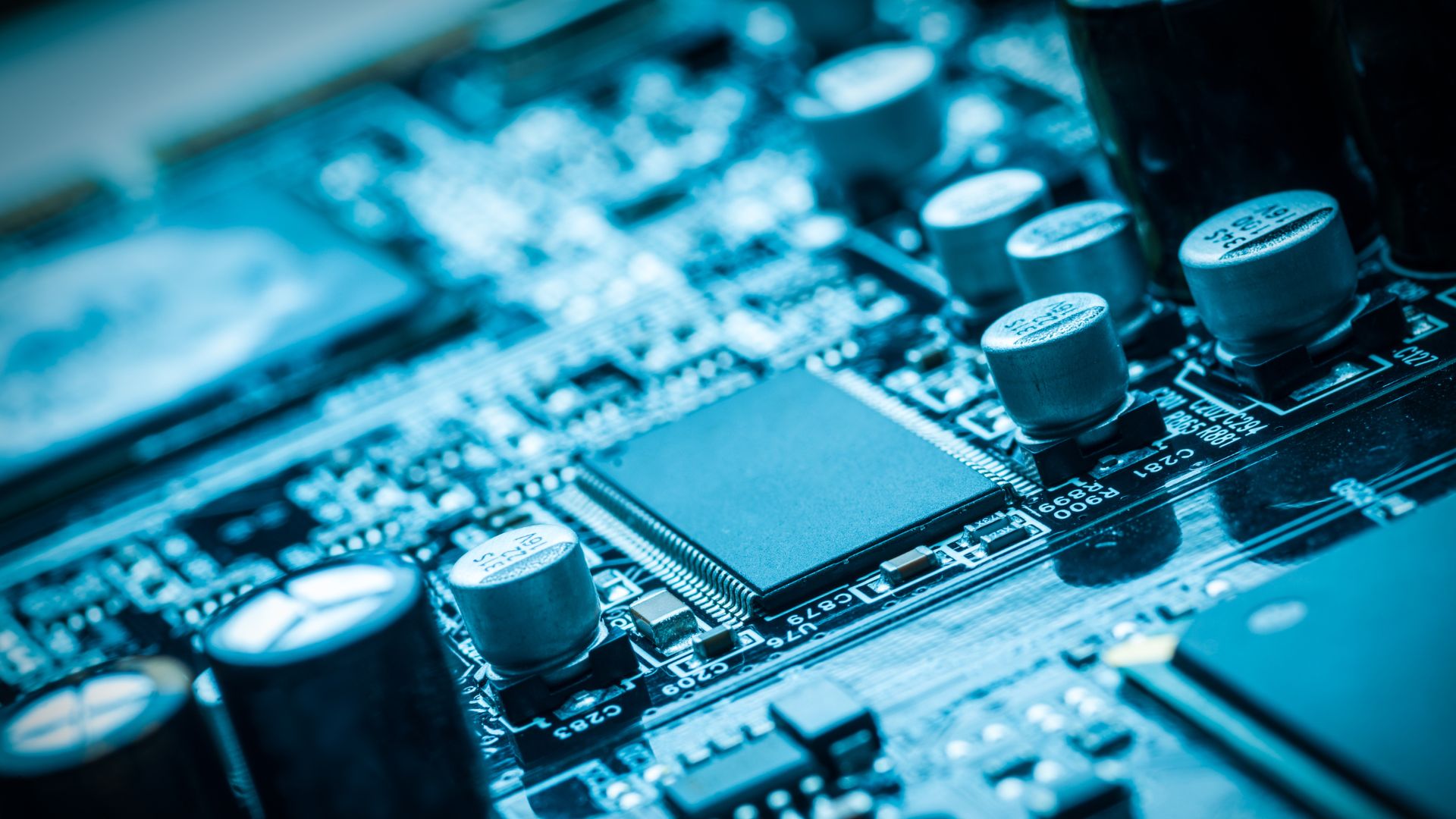

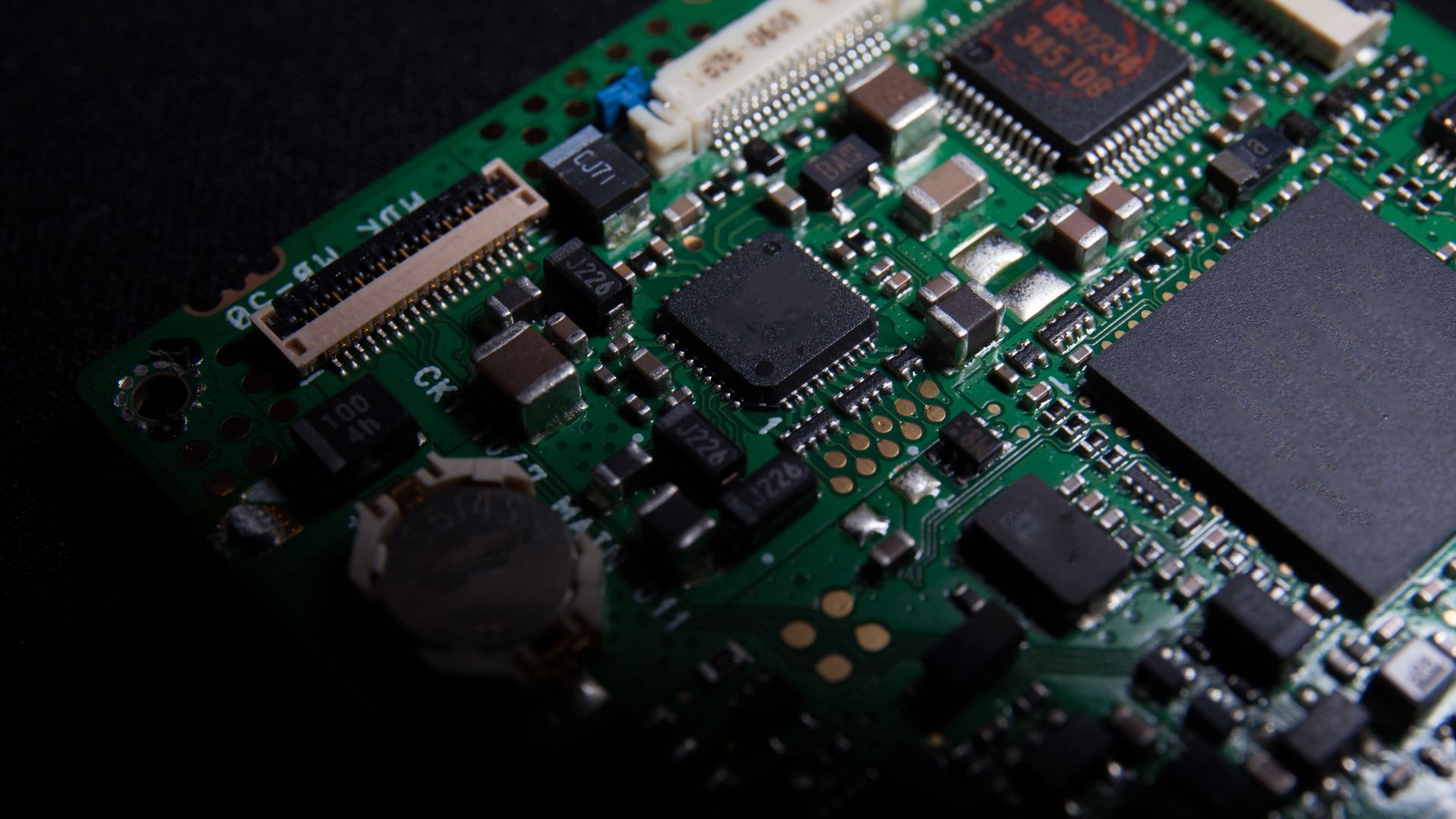

Testing is a critical phase, ensuring that each chip functions correctly before it moves on to the final stage: integration. Once a microchip passes all quality checks, it is integrated into electronic systems, from smartphones to satellites. Here, it plays a pivotal role in processing data, controlling operations, and connecting devices in our increasingly digital world.

The lifecycle of a microchip is a remarkable journey, transforming raw silicon into the brains of modern technology. Each step is a testament to human ingenuity and the relentless pursuit of innovation.